Global Forum For Indurstrial Devlopment is SPONSORED BY ICO INDIA

- MP Society Registration (Act. 1973 No. 44) 03/27/01/21857/19 (MSME Forum Established Since-2009)

Electrical supplies require sophisticated manufacturing process to assure product failure safety protection at all levels. To avail such a benefit, explore the widest range of Electronic Electrical Supplies like LED products, electronic products, electrical goods & equipment, wire & cables, & others. Explore various types of electronic & electrical products featured by different world’s finest brands.

Keeping the online marketing trends in vision, we bring a well-defined online business directory of electrical & electronics. This online directory gives you a complete access to the productive database of varied service providers who are engaged in providing services for electrical & electronics. The various categories available here include electrical components, electrical services, lamp parts, etc. The companies who are doing their business through SME are the leading providers of the services from all over the world. This directory gives an access to the buyers to search & find to the electronic products manufacturers, electrical Goods Suppliers, exporter, wholesaler of electronics & electrical from all over the world. This directory provides a platform for the sellers from all over the world to add their business for inviting the interested buyers to buy their products. The section of trade leads is designed here where buyers can post online trade leads for their desired product and services. Sellers can invite buyers to buy their offered services and products via trade leads.

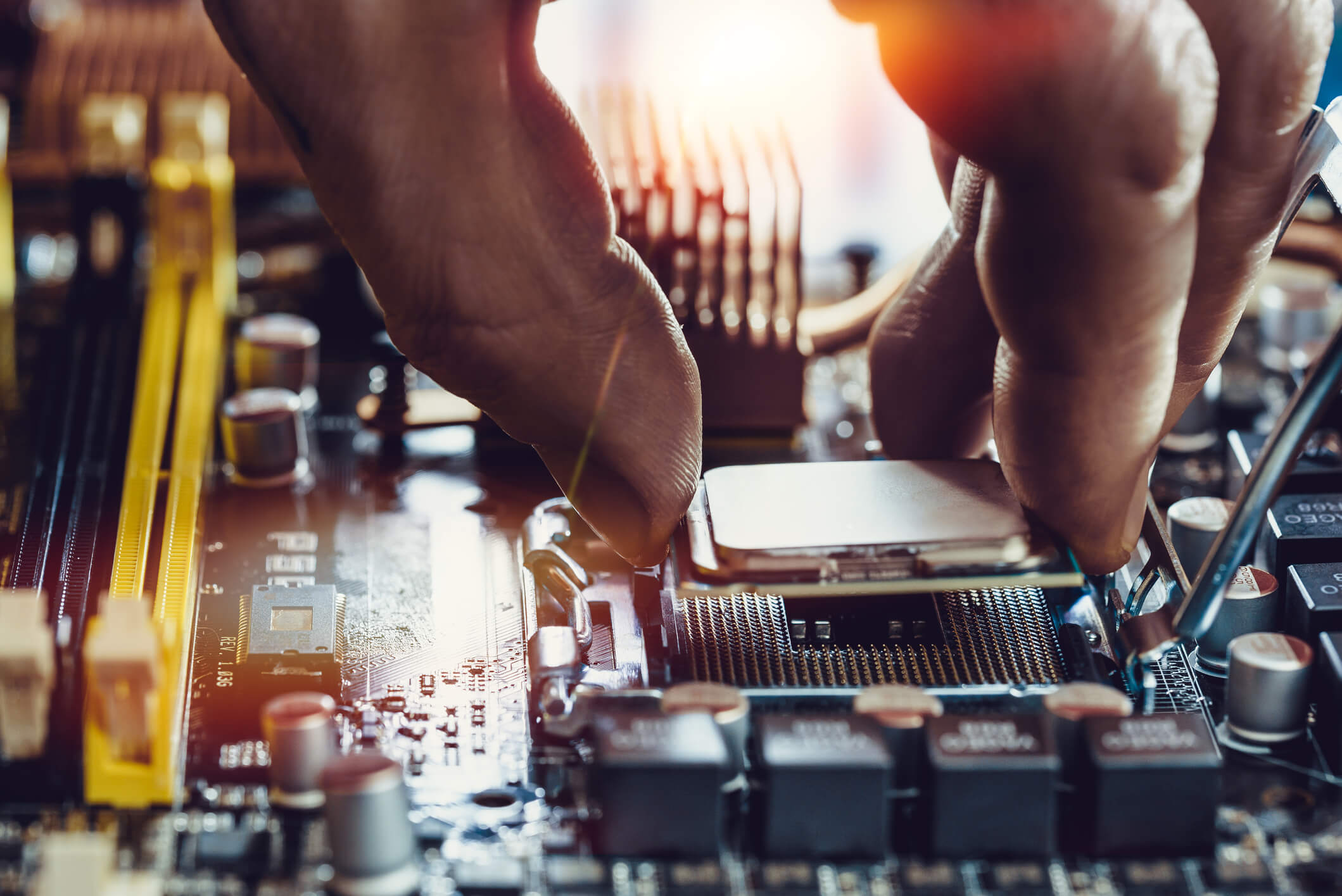

Technical advances are a constant occurrence in the electric and electronics industry and in component manufacture. In these fields, the functionality and capabilities required from the manufacturing equipment utilized in processing, assembly, inspection and other various phases are becoming ever more sophisticated.

1. Operation Management

We raise the value of manufacturing operations and contribute to society using measurement, control, and information technology to optimize the relationships between the five assets (raw materials, energy, equipment, products, and workers) that are basic to all manufacturing sites

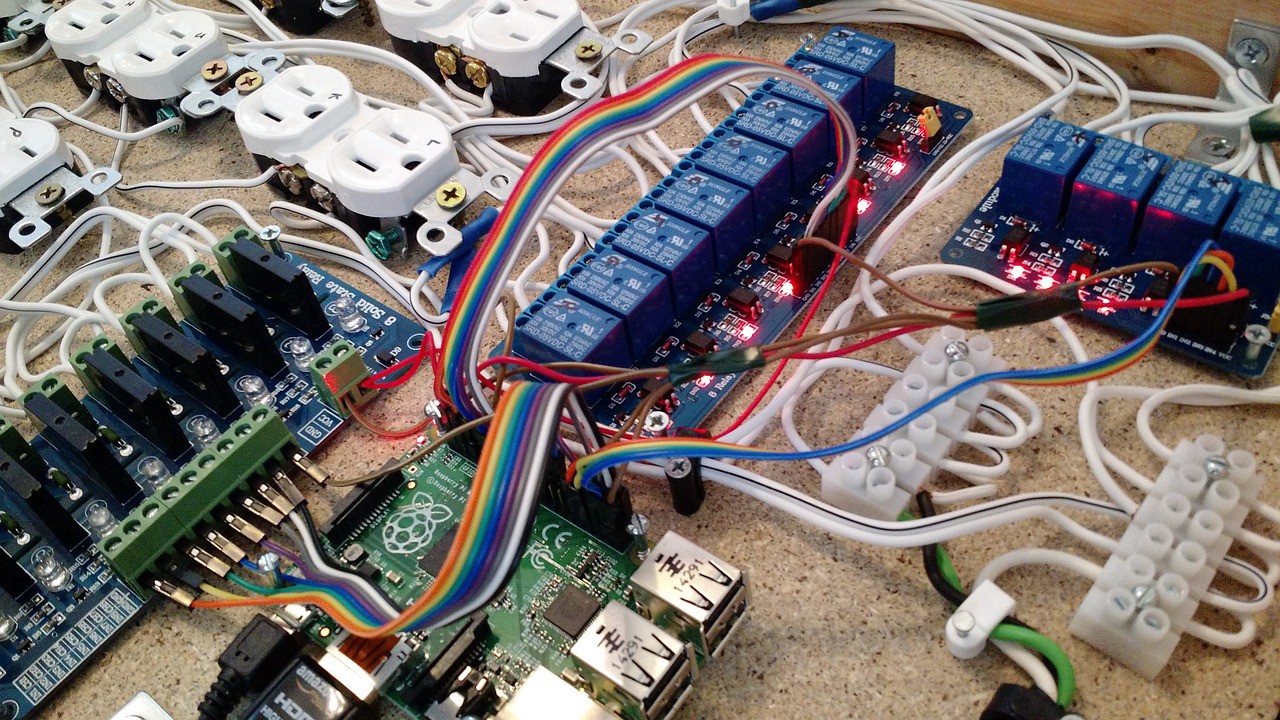

2. Supports high-usage high-availability industrial automation control and distributed control that achieves safe and stable production.

3. Information management assistance for more efficient plant operation and improved profitability, with support for all kinds of manufacturing-related information.

We help to create value in the electric and electronics industry not merely by providing products, but also by solving diverse problems through provision of services such as optimization diagnosis for control systems, which can be done before manufacturing equipment problems begin. Other solutions provide support for onsite control adjustment, in addition to more advanced solutions such as control links between devices, which are nowadays in great demand, as well as control that optimizes energy efficiency, and support for better visualization of control systems through instrumentation networks

Electronic coils are a type of electrical conductor. Also known as magnetic coils or electromagnetic coils, they get their name from the shape in which they are wound. This shape is a coil, also known as a spiral or a helix. Electric coils are mainly designed to transmit electricity, heat or sound. Also, they are generally used to produce movement, regulate flow and/or transform electric currents in applications related to telecommunications, computers and appliances. Typically, theyÂ’re made from metal wire.

Electric coils can work in a few different ways. Some work when an electric current passes through them and creates a magnetic field. Others work when theyÂ’re fed by a voltage-generating time-varying magnetic field. In this scenario, the field is found outside of the coil, but the voltage passes through it.

lectric switches are electrical components designed to safely open or close an electrical circuit. Note that an open electrical circuit is not connected, while a closed circuit is connected. So, though it seems counterintuitive, if a circuit is open, current cannot pass through it and it is not working. Likewise, if a circuit is closed, current can pass through it and it is working.

Electric transformers electrical devices that transfer electrical energy between two or more circuits. They can also increase, decrease, isolate, pattern and translate electrical currents of all power levels. The purposes of such actions are to make sure that they match the voltage and the voltage safety requirements of any given piece of equipment.

Electronic transformers serve every piece of equipment that is powered by electricity. This is because the transformers provide electrical equipment with the current to voltage conversions that they require. Transformers are also important in the storage and transportation of energy in power lines and power grids.

To meet the needs of their innumerable applications, electronic transformers are configured using countless designs. They vary in many ways, including by: frequency range, voltage class, basic magnetic form and general winding configuration. Examples of transformer types include: step up and step down, polyphase, toroidal and zig zag transformers. Generally speaking, though, electric transformers consist of the following components: a core and windings. Among other materials, the core may be made of laminated steel, powdered iron or non-conductive magnetic ceramics (ferrites). Windings serve to minimize the leakage of inductance. In addition, very large transformers are equipped with high voltage insulated bushings.

.jpg)

Composed simply of plugs and jacks, they do so by conducting electricity between said terminations. In this context, the circuits may come in the form of cables alone, or they can manifest as one cable and one electrical terminal.

Regardless, there are three main types of electronic connectors: temporary connectors, permanent connectors and assembly required connectors. The first type of connector is mostly used in portable equipment, where it can expect its lifespan to be relatively short. Permanent connectors, on the other hand, are placed in equipment or applications where they are expected to function successfully for a long time. Finally, assembly required connectors are just as they sound. They require assembly. Typically, they are best used in applications that, while trusting in longevity, plan for the option of removal or replacement down the road. In addition, some electronic connectors are made to fit specific applications. Examples of electronic connector applications include: DIN connectors for loudspeakers, PCB connectors for printed circuit boards and connectors for military equipment. To make connectors appropriate for the military, manufacturers use specific materials and sizes that meet military specifications.

It’s worth mentioning that every time you make an API call, it costs a fraction of a cent. Large companies are providing these cognitive services at little cost as part of their enhanced suite of cloud offerings. For the most part, you are not required to sign up for lengthy contract terms, meaning that the barrier to entry for using these technologies is extremely low.

Electronic components typically found housed within electronic enclosures include audio equipment, switches, computer servers, conduits and general connections. Because electrical equipment is so sensitive, electronic enclosures are important components of electrical equipment used in many industries. These industries include industrial manufacturing, healthcare, agriculture, automotive engineering, transportation and more. Basically, though, theyÂ’re found anywhere there is electronic equipment, including in the home, in commercial buildings, in libraries and in stop lights.